Epiphone 335 Snapped Headstock Repair with Splines

South Austin Guitar Repair

Broken headstocks can be devastating. Guitars with angled headstocks are one accident away from certain doom. It can happen anywhere, and any time. You may see it as it happens – after playing the last song of your set, you prop your guitar against your amp, only to be bumped by the drummer exiting the reiser behind and knocks it to the floor of the stage. Or the time your dog, or kid are running through the house graze the tripod stand just enough. Or when traveling by plane, you didn’t know to loosen the strings before checking your hard case with the luggage that goes into the freezing belly of the plane. Seeing your beloved guitar broken, always hits hard.

|

|

|

|

And for a guitar repairman like me, it’s just another Tuesday. Angled headstocks are built in business that will always be there as long as there are people playing guitars. The angled headstock certainly has its benefits. The string break angle allows a cleaner look to the headstock, not requiring string trees to combat the string buzz between the nut and tuners. It’s a scarf joint construction, which many luthiers pride themselves in implementing. Most of all, it has the “it” factor that has made so many guitars achieve their aesthetic. You know those models.

|

|

|

|

In many cases, headstocks break at a diagonal angel. You can often apply glue in the break, clamp overnight, and structurally, it’s good to go. Most folks opt to cover over the break with some touch up sanding and finish work to hide the damage, but it is certainly not necessary for those who are cost conscious.

This type of break, however, needs extra love to get back to playing. It’s a vertical break. They don’t happen nearly as often as the angled ones, and it’s the result of poor wood grain choice made by the manufacturer. In this case, because the finish covered any visibility of the neck’s wood grain pattern, someone at the factory got away with it. The moment this guitar suffered its fate, was uneventful. The customer was loading the guitar, which was in a hard case, into his car. There was just enough “umph” when throwing it into his trunk, when he opened the case, there it was. In two pieces.

|

|

|

The first step in this repair is getting the parts back together. The wood fibers were many, and splintered off in a few directions from the break. Using my ape brain, I fit the headstock back into place and wiggle it around, trying to find the traces of where all these fibers originally met. Eventually, when I find the right fit, I separate the two pieces, apply glue into the peaks and valleys of both ends, then fashion them back together. I use a series of clamps to maintain pressure, and forgot to snap a pic of them. Oops.

|

|

|

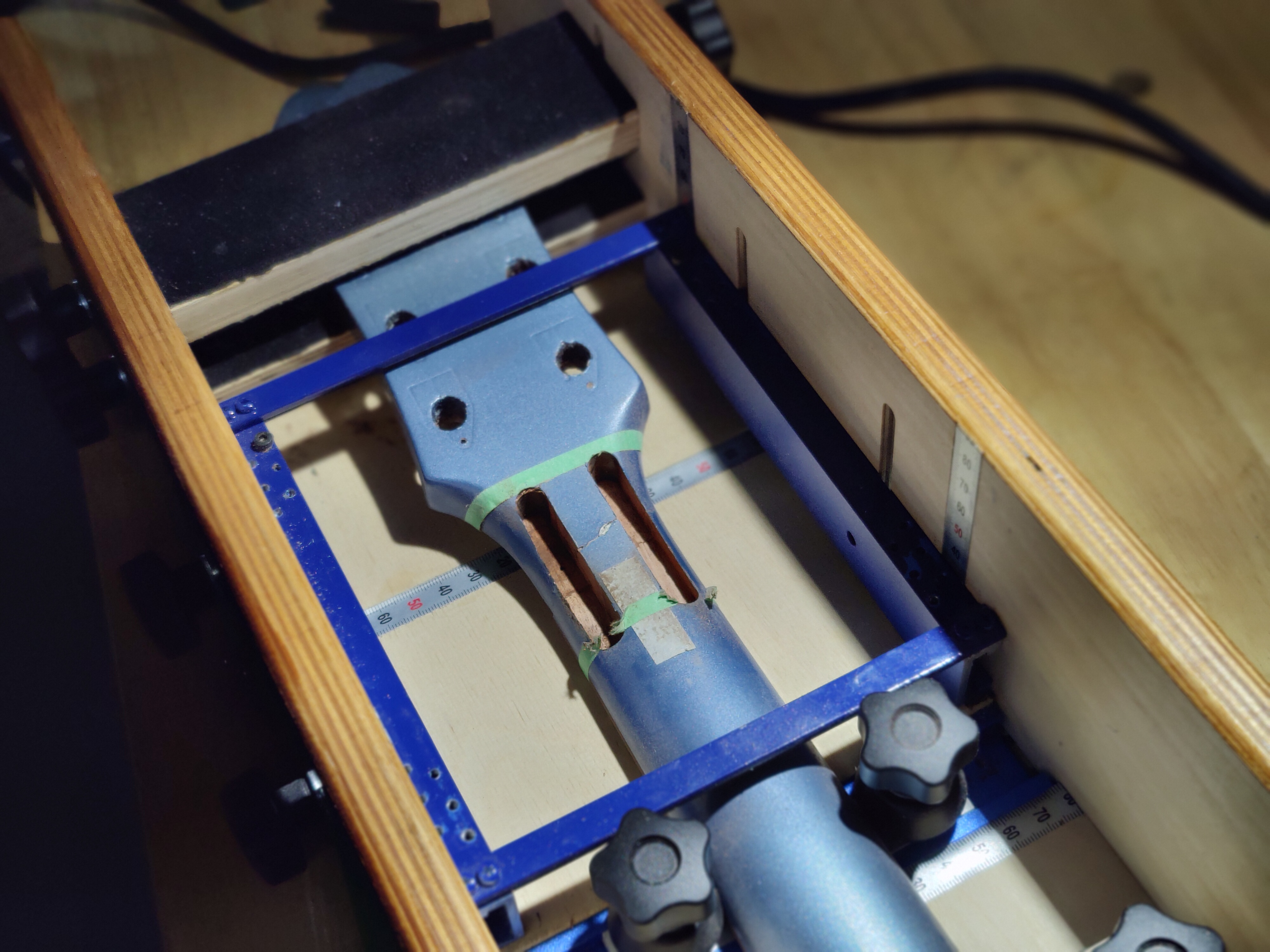

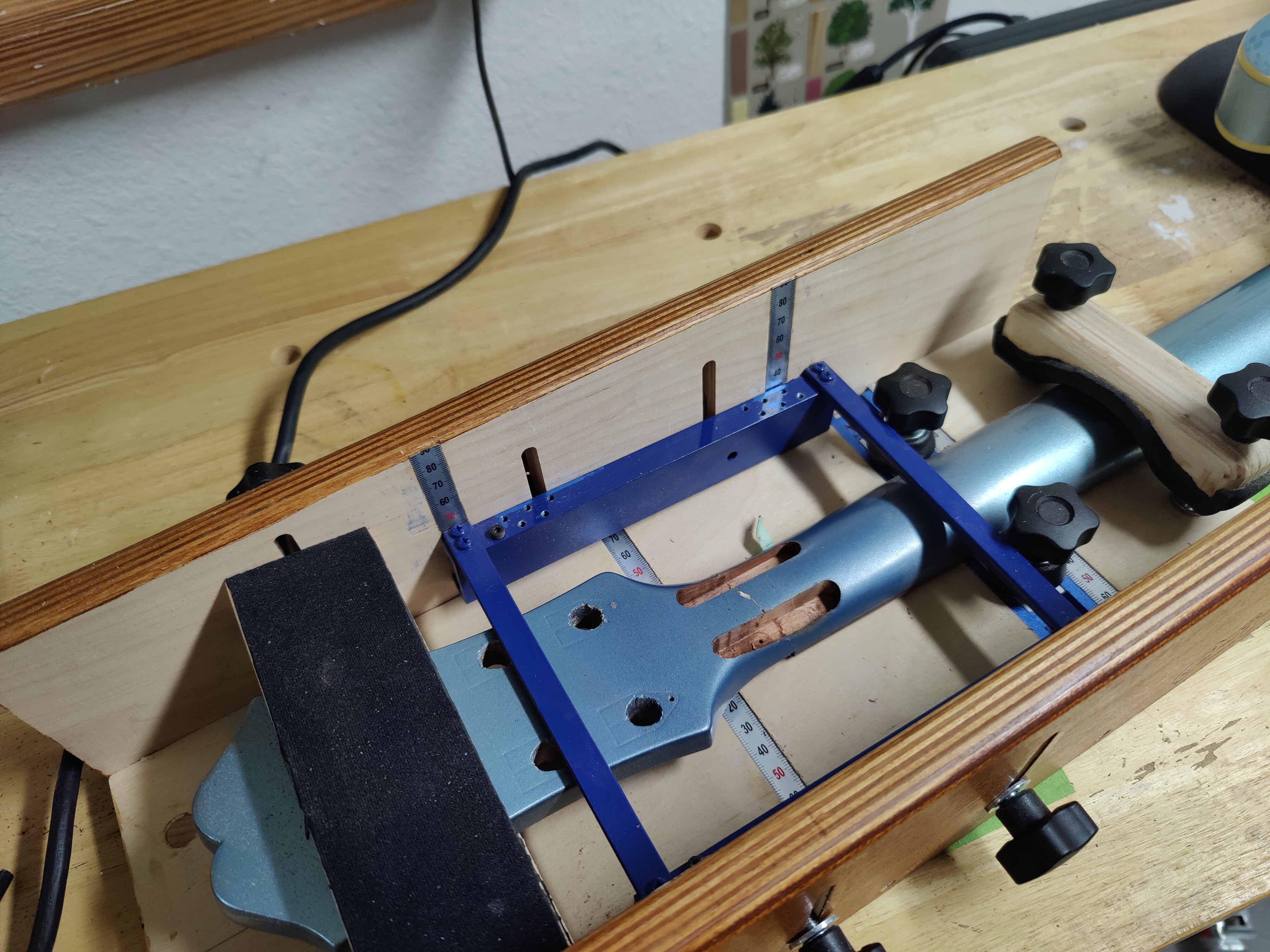

The following day, I measure and mark off where the truss rod sits on the back of the headstock with a piece of tape. Now, the real fun begins. Using my neck spline routing jig, I route two channels in between the edges of either side of the neck and the tapped off truss rod area. Next, I begin cutting the plugs using a particularly dense, hard rock maple. I shape it to a rough size on my drum sander and make the final refinements by hand with sandpaper on a flat surface. When I achieve a snug fit, I use a “shoeshine” sanding technique to round the squared edges.

Once I have maple splines with a snug fit, they are glued and clamped into place. The next day, it’s time to carve! Using a seriously sharp sloyd knife, I begin removing material from the splines, a little at a time and carve them into the geometry of the neck. Eventually, they are just above the threshold and I can use scrapers and sanding blocks to get them even with the surrounding surfaces. The neck is now ready for some finish coats to cover the break.

|

|

|

|

The good people at Gracey’s Finishes have meticulously matched all of the iconic guitar finishes over the decades, and from my research, the only ones with a matching Pellham Blue lacquer to make the fix. Thank you guys!

This headstock break, though challenging, doesn’t mean the guitar is beyond repair. When re-gluing a broken headstock, the most important factor is having fresh, un-touched wood to apply glue for adhesion. Glued joints are surprisingly stronger than the original wood fibers of the neck. Adding splines from dense hardwoods will certainly reinforce the break. When it comes to the dreaded vertical break, they are a must. After some time and care with touch up work, the neck was better than new.

Does your guitar neck need splines to reinforce a break?

Call Andrew with South Austin Guitar Repair. 512-590-1225.

The face of the headstock is all in place and without damage. The crack damage is all concentrated on the backside of the headstock(at the opposite side of truss rod cover). The guitar is a Gretsch 6120 RH model. Without success, I tried to attach photos (by drag & drop)onto this msg. Please advise when time allows. Thank you.

Apologies John. I just saw this now. Feel free and give me a call if you’re still in need of the work.